Artificial Intelligence in Manufacturing

Optimize production. Minimize downtime. Accelerate growth.

Empowering manufacturers with AI-driven insights to streamline operations and deliver measurable impact.

Accelerate Your Path to Digital Transformation

USM’s AI-powered solutions help manufacturers automate production, optimize operations, and make smarter, data-driven decisions. By combining AI, analytics, and automation, we deliver scalable solutions that reduce downtime, cut costs, and improve efficiency.

With deep expertise in building custom AI applications for manufacturing, we empower enterprises to modernize processes, integrate seamlessly across connected ecosystems, and unlock measurable business impact.

Headquartered in the U.S. with offices in Chantilly, Virginia; Frisco, Texas; California; and New York, USM is your trusted partner in AI-driven manufacturing transformation.

David and John’s Transformation

How two manufacturers overcame production bottlenecks and boosted productivity by 60%.

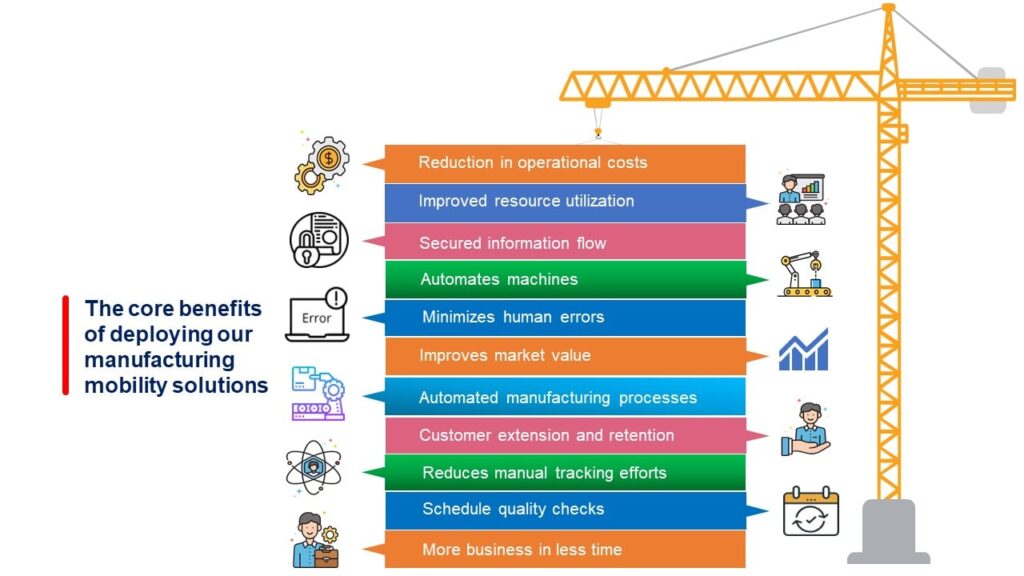

Why Mobility Matters in Manufacturing

Modern manufacturers face critical challenges: enhancing productivity, streamlining on-field operations, managing warehouses, and ensuring workplace safety. USM’s AI-driven Mobility Solutions address these pain points, driving measurable outcomes.

Key Benefits of Our Manufacturing Mobility Solutions:

- Cut Operational Costs: Eliminate inefficiencies with AI-enabled automation.

- Maximize Resource Utilization: Optimize workforce and asset performance.

- Secure Data Flow: Ensure safe, real-time information exchange.

- Automate Machines & Processes: Reduce manual effort and downtime.

- Minimize Human Errors: Improve accuracy and compliance.

- Boost Market Value: Strengthen competitiveness with smart manufacturing.

- Enhance Customer Retention: Deliver better service through actionable insights.

- Streamline Tracking & Quality Control: Automate audits and monitoring.

- Accelerate Business Growth: Achieve more in less time with scalable mobility.

0 +

0 +

0 +

Let’s talk About your project

Understanding your requirements and objectives is important to us. We listen and work together to create a truly unique experience.

Let’s Start Work together!

Our Clientele

At USM, we combine deep expertise with a client-first approach to deliver technology solutions that create lasting impact. Our work has earned the confidence of organizations worldwide.

Why choose USM for your Services?

As a reputed AI mobile app development company, USM has flexible engagement plans for software development projects which are customized according to client specifications.

- 24X7 Support

- Certified Resources

- Predict Trends

- Customer Service

- Actionable Insights

- Diverse Industry

Segments We Have Experience In

USM helps accelerate innovation and gratify industry specific best practices to help run your core business efficiently.

Agentic AI in Manufacturing Use Cases

AI in Manufacturing: Not Just a Technology; It’s A Future for Manufacturing.

Is your manufacturing plant struggling with unnoticed material weight variances? What if your systems automatically detect those issues before they impact on production ratio? That’s where USM’s AI solutions come in. Our intelligent, tailored AI models revolutionize your manufacturing processes with real-time monitoring, forecasted insights, and maximized efficiency.

One of our major manufacturing clients had faced difficulties in handling huge volumes of raw material data which is generated from over 400 storage tanks. On top of that, hidden weight variations due to faulty sensors when transporting raw materials resulted wrong production ratios and costly material losses.

USM Business Systems provided a new Agentic AI-driven solution which processes large amounts of data throughout manufacturing plants to detect differences in material weights. It identifies root causes like environmental effect, sensor fault, transmission leaks, or vendor level fraud through predictive analysis reports.